Tackling thermal management challenges in portable fuel cell reactors

Researchers have developed a safer and thermally resistant microreactor to power smart devices with fuel cell-compatible fuels

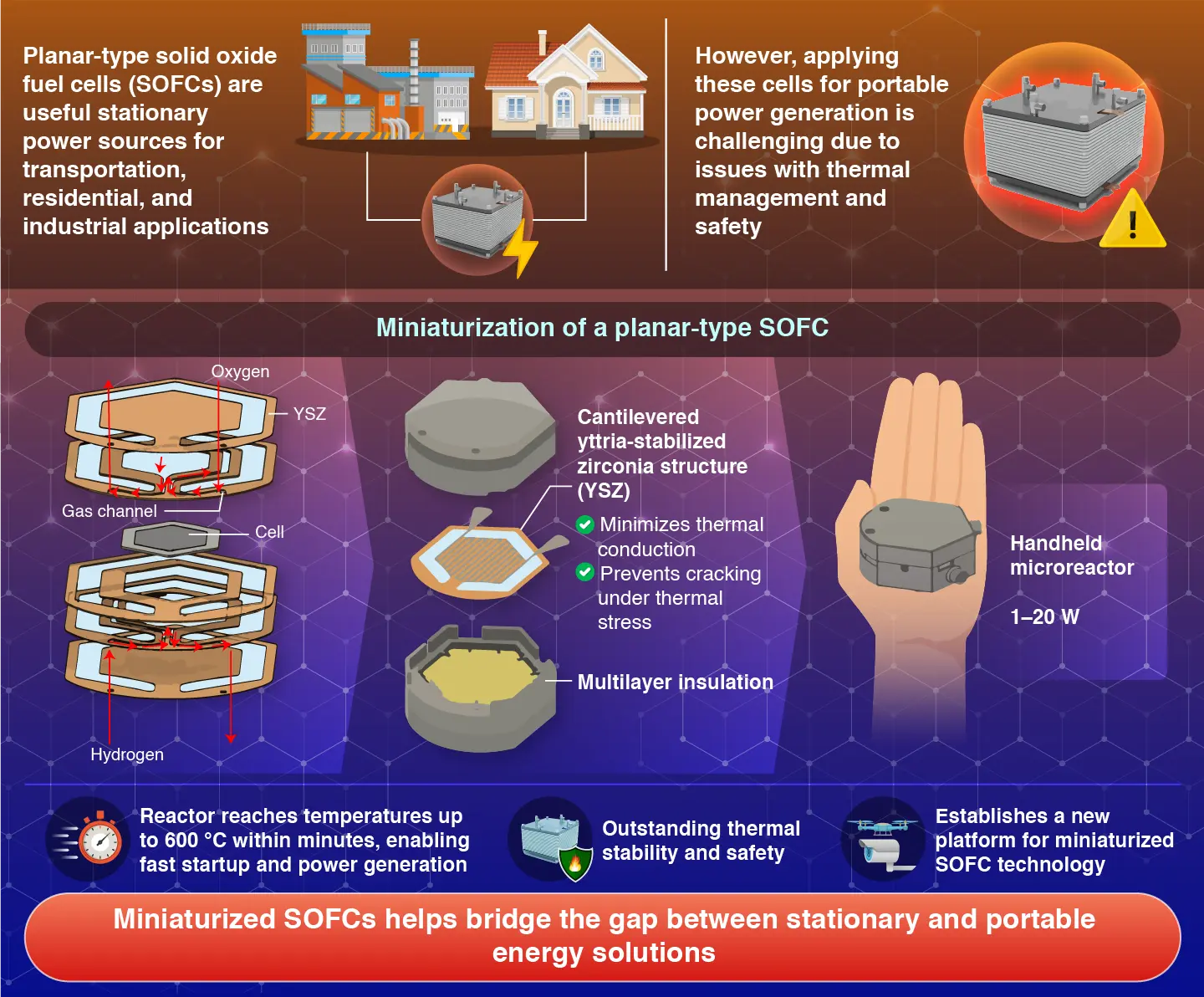

A new portable reactor based on solid oxide fuel cell solves thermal management and safety issues, as reported by researchers from Japan. This miniaturized reactor can start up rapidly within 5 minutes at room temperature and demonstrate electric power generation. Featuring an innovative structural design with high thermal insulation and a multilayered insulation system, this microreactor design could be used to power a wide variety of edge devices, including drones, compact robots, and AI hardware.

Towards Palm-Sized Microreactors for Powering Portable Devices

As the digital age progresses, humanity is witnessing a massive increase in the number of edge devices, from smartphones and drones to compact robotics and artificial intelligence hardware. These technologies often require portable power sources with high energy density—a demand that conventional battery technologies are ill-prepared to fulfill. Lithium-ion batteries, for example, are already hitting their theoretical limits, yet they still cannot sustain long drone flights. To overcome this, scientists have focused on solid oxide fuel cells (SOFCs) as a next-generation power source. These devices convert hydrogen-rich fuels directly into electricity with high efficiency and energy density, reaching gravimetric energy density up to four times that of existing batteries.

Despite their immense potential in edge devices, SOFCs have been mostly confined to large-scale stationary or industrial applications. Since SOFCs operate at high temperatures exceeding 600 °C, miniaturizing SOFC-based reactors for handheld use creates massive thermal stress due to the steep temperature differences that exist between the inside and outside materials. This stress causes conventional designs to crack and fail, posing serious safety concerns.

In a recent effort to address this challenge, a research team led by Dr. Tetsuya Yamada from the Laboratory for Future Interdisciplinary Research of Science and Technology, Institute of Science Tokyo (Science Tokyo), Japan, has successfully developed a palm-sized SOFC microreactor. Published in the journal Microsystems & Nanoengineering in December 2025, their study introduces an innovative design that solves the problem of thermal stress, as well as a clever insulation solution to keep the outside of the device cool and safe to touch.

Central to their solution is the adoption of an yttria-stabilized zirconia (YSZ) ceramic structure with a cantilevered shape. This heat-resistant structure minimizes thermal conduction and prevents cracking under thermal stress. Based on this, the researchers developed a YSZ ‘scaffold’ capable of housing a button-type planar SOFC while also providing microchannels for the flow of hydrogen, oxygen, and water.

The team paired this robust design with a lightweight multilayer insulation system to suppress radiative heat losses, essentially isolating the extremely high temperatures in the SOFC from the outside world. The final device could reach its operating temperature of 600 °C within 5 minutes—a significant speedup compared to the half hour required by most large SOFC reactors. “By scaling down conventional stationary fuel cells to a palm-sized form factor, this work opens the path toward portable energy systems and demonstrates the potential for high-energy density, off-grid power sources capable of directly supplying electricity to edge devices,” remarks Yamada.

Notably, the researchers also demonstrated an inherent safety mechanism against rapid thermal ramping. "When the insulation structure is punctured, the loss of thermal insulation causes a rapid temperature drop, bringing the system below the temperature range associated with hydrogen ignition risks within 5 minutes and preventing potential hazards," notes Yamada.

Overall, this work establishes a new, scalable platform for miniaturized SOFC technology, paving the way for the next generation of safe power sources for robotics, drones, and future AI edge devices.

Reference

- Authors:

- Bishnu Choudhary1, Gia Ginella Carandang1, Shinichi Yamagishi2, Saki Tada2, Chie Kawamura2, Yasuko Yanagida1, and Tetsuya Yamada1*

*Corresponding author - Title:

- A high-thermal-insulation and portable microreactor for integrating widely used planar-type SOFC and enabling handheld power generation

- Journal:

- Microsystems & Nanoengineering

- Affiliations:

- 1Laboratory for Future Interdisciplinary Research of Science and Technology, Institute of Science Tokyo, Japan

2Materials Research and Development Department, TAIYO YUDEN CO., LTD., Japan

Related articles

Further information

Assistant Professor Tetsuya Yamada

Laboratory for Future Interdisciplinary Research of Science and Technology, Institute of Science Tokyo

Contact

Public Relations Division, Institute of Science Tokyo

- Tel

- +81-3-5734-2975

- media@adm.isct.ac.jp