Enhancing hydrogen production using modified ilmenite oxygen carriers

The iron-substituted calcium-titanate phase achieved in modified ilmenite improves carbon dioxide capture, hydrogen output, and energy recovery

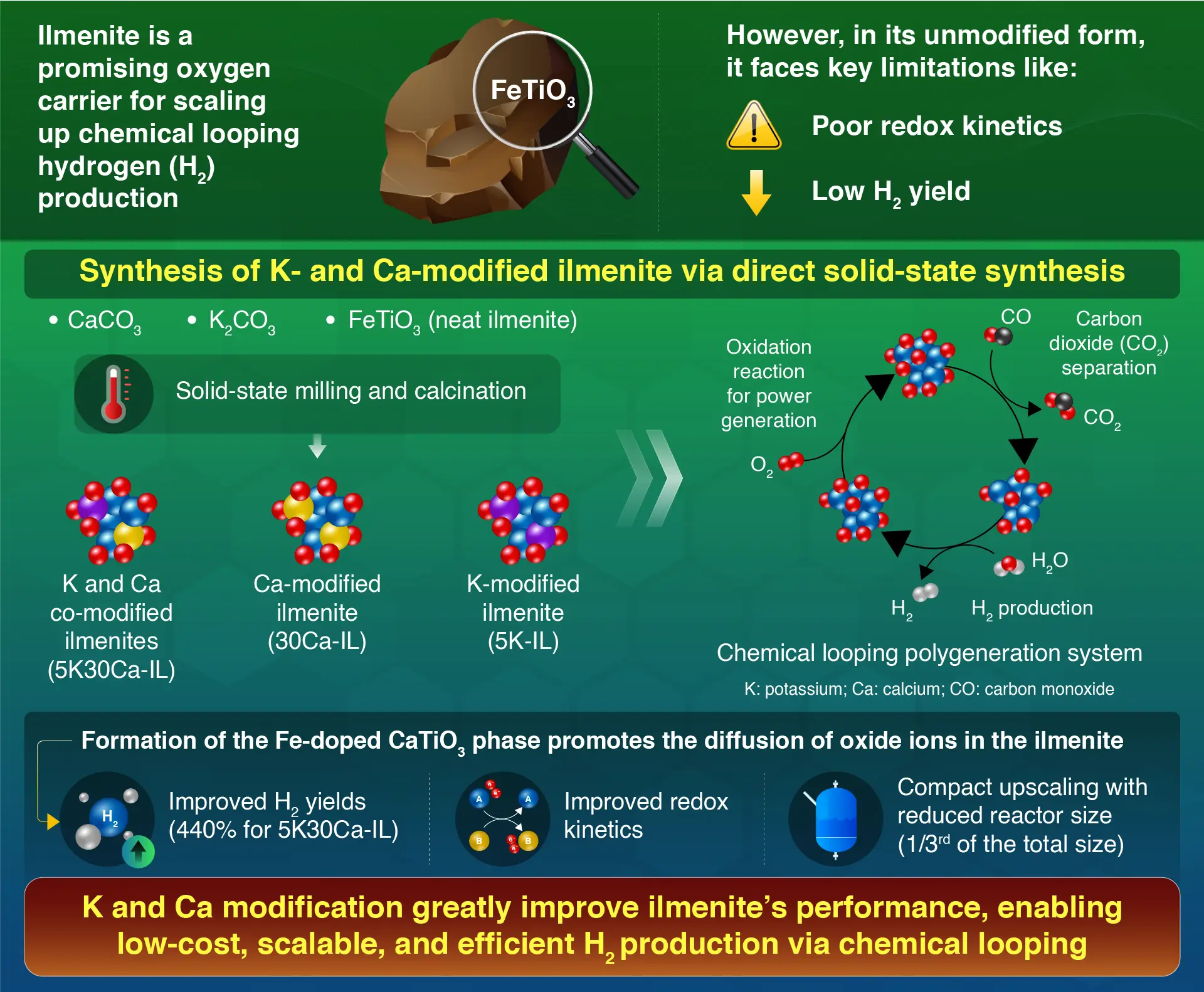

Potassium- and calcium-modified ilmenite oxygen carriers, developed by Institute of Science Tokyo, significantly improve hydrogen yields and redox reaction efficiency in chemical looping systems. The chemical modification of ilmenite results in the formation of a calcium titanate phase with iron substitution. This advancement enhances the oxide ion diffusion, accelerates hydrogen production, and also enables a polygeneration system for simultaneous hydrogen production, carbon dioxide capture, and power generation—paving the way to scalable, carbon-neutral energy systems.

Unlocking Efficiency: K- and Ca-Modified Ilmenite for H2 Production

Sun and Otomo (2025) | Applied Energy |10.1016/j.apenergy.2025.126362Potassium and Calcium-Modified Ilmenites for Improved

Hydrogen is often known as the clean fuel because when it burns, it doesn’t release carbon dioxide (CO2), unlike other fuels. However, producing clean hydrogen without carbon emissions is quite challenging. One promising solution is chemical looping hydrogen production, an advanced energy conversion system that allows simultaneous capture of CO2, hydrogen production, and power generation using circulating oxygen carriers. However, finding efficient and scalable oxygen carriers with high performance in chemical looping has remained a challenge until now.

To address this, a group of researchers led by Professor Junichiro Otomo, along with researcher Dr. Zhuang Sun from the Department of Transdisciplinary Science and Engineering, Institute of Science Tokyo (Science Tokyo), Japan, developed a modified oxygen carrier that could dramatically improve hydrogen production and chemical looping outcomes. Their findings were made available online in the journal Applied Energy on July 04, 2025, and will be published in Volume 398 on November 15, 2025.

Chemical looping systems typically involve three interconnected reactors: a fuel reactor that converts carbon monoxide (CO) to CO2, a steam reactor for hydrogen formation, and an air reactor for power generation. These reactors continuously circulate metal oxides (oxygen carriers) which drive redox reactions without direct combustion, allowing efficient CO2 isolation and sustainable hydrogen production. Ilmenite is a natural mineral-based oxygen carrier that shows promise in chemical looping for hydrogen production. However, it often suffers from sluggish kinetics and poor hydrogen yields, making it less ideal for industrial-scale use.

To overcome this, the researchers modified the structure of ilmenite by adding potassium (K) and calcium (Ca) into its structure using a solid-state synthesis method. “We chose Ca and K ions for modifying ilmenite,” explains Otomo. “Since both are major components of biomass ash, this could facilitate better integration with renewable fuels.”

Briefly, the researchers first treated the natural ilmenite to remove impurities. The treated ilmenite was blended with specific amounts of calcium carbonate and potassium carbonate in a ball mill and calcined at high temperatures (900 °C and 1,300 °C) to form K-modified, Ca-modified, and K-Ca co-modified ilmenites. This modification introduced a new phase called calcium titanate with iron substitution within the structure.

“This iron-doped calcium titanate phase plays a critical role in accelerating the redox reactions in hydrogen production because the iron-doped calcium titanate is an ionic and electronic conductor,” notes Otomo. “By promoting the diffusion of oxide ions, we achieved a much higher reaction rate and hydrogen yield compared to conventional ilmenite-based carriers.”

In effect, this research marks a significant milestone in material science and clean energy. The new oxygen carriers are not only scalable but also cost-effective. Particularly, the optimized K-Ca co-modified ilmenite dramatically improved the efficiency by 5.5% in a polygeneration process. It reduced the CO consumption by 57% while boosting the hydrogen production by ∼440%—all within just one-third the size of a full-scale reactor. Furthermore, this new oxygen carrier is expected to have widespread applications in polygeneration systems for clean energy generation.

Looking ahead, the team aims to develop lower-temperature synthesis methods for cost-effective scaling. “A major step forward would be in July 2025, when a demonstration project led by Osaka Gas Co., Ltd. and JFE Engineering Corporation, with support from the Japan Carbon Frontier Organization, is expected to begin,” remarks Otomo. This project will use the newly developed material to simultaneously generate hydrogen, electricity, and CO2 from biomass and liquid waste.

Additionally, Science Tokyo’s Green Transformation Initiative (Science Tokyo GXI) is also supporting the effort by expanding its experimental facilities. A demonstration experiment with a large-scale fluidized bed reactor is in progress at the university to refine the technology for practical settings. Building upon further collaborations, the team hopes to accelerate polygeneration technologies for a sustainable future.

Reference

- Authors:

- Zhuang Sun1 and Junichiro Otomo1*

- Title:

- Potassium and calcium-modified ilmenites for improved reactivity and

hydrogen yield in chemical looping - Journal:

- Applied Energy

- Affiliations:

- 1Department of Transdisciplinary Science and Engineering, School of Environment and Society, Institute of Science Tokyo, Japan

*Corresponding author

Related articles

Further Information

Professor Junichiro Otomo

School of Environment and Society, Institute of Science Tokyo

Contact

Public Relations Division, Institute of Science Tokyo

- Tel

- +81-3-5734-2975

- media@adm.isct.ac.jp